BEZ-series

Mounting Kits

for Displays

Protect and enhance the appearance of LCDs, OLEDs and VFDs with a custom faceplate and mounting hardware.

In Stock, 6.00-16.00 Buy Now

More Information

- Dimensions

- Faceplate Dimensions, PDF

Mounting Kits and Faceplates by Part Number

| BEZ-216 (for BPI-216N/L, GLO-216Y/G) |

•Self-adhesive 20-mil Lexan faceplate, 82x38mm •Four 3/16"-dia. spacers, 0.188" •Four 3/16"-dia. spacers, 0.375" •Four 5/8" 2-56 machine screws •Four 2-56 machine nuts Instructions |

11.00 ea |

|---|---|---|

| FPL-216 (faceplate only) | •Self-adhesive 20-mil Lexan faceplate, 82x38mm | 6.00 ea |

| BEZ-420 (for BPP-420L/VY and VFD-420) |

•Self-adhesive 20-mil Lexan faceplate, 102x64mm •Four 3/16"-dia. standoffs, 3/8" long, 2-56 •Four 1/4" 2-56 machine screws •Four 2-56 machine nuts Instructions |

16.00 ea |

| FPL-420 (faceplate only) | •Self-adhesive 20-mil Lexan faceplate, 102x64mm | 11.00 ea |

| Add'l Info Link | Faceplate Dimensions | |

BEZ-series Application and Use

Sharp tools, curious fingers, water, grit, electrostatic discharge—any of these can wreck an LCD, VFD or OLED. In commercial gear displays are mounted behind a transparent window to protect them from environmental hazards. If you're making a prototype or instrument, our mounting kits may be just the ticket.

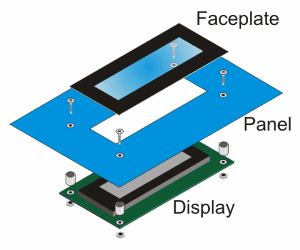

The illustration above shows the basic principle: Each kit includes a self-adhesive Lexan faceplate 0.020" thick. It serves as a window to view the display, and an opaque black border hides the countersunk heads of the mounting screws. The "panel" is your mounting surface, ideally between 0.0625" and 0.080" thick (common for electronic enclosures). BEZ- packages includes appropriate machine screws (2-56 or 4-40, depending on the display) and spacers as needed.